How Much Flashing Must Be Behind Cement Siding And Roof

There are many different metal flashing shapes but in your case the metal laps over the fascia board perhaps 1 4 inch then is bent at a 90 degree angle to pass over the top of the fascia board then bent again at a 90 degree angle to go up the wall so that it extends behind the first row of vinyl siding.

How much flashing must be behind cement siding and roof. Flashing a wood framed chimney is like flashing a dormer except there s no roof behind it to direct uphill water away without protection water can leak into the joint and rot your walls. There are a few general best practices you need to know. Step flashing is the most time consuming of all flashing jobs on the roof because you must complete it step by step as you shingle up the roof. When it comes to flashing siding corners many builders simply use a 1x wood corner.

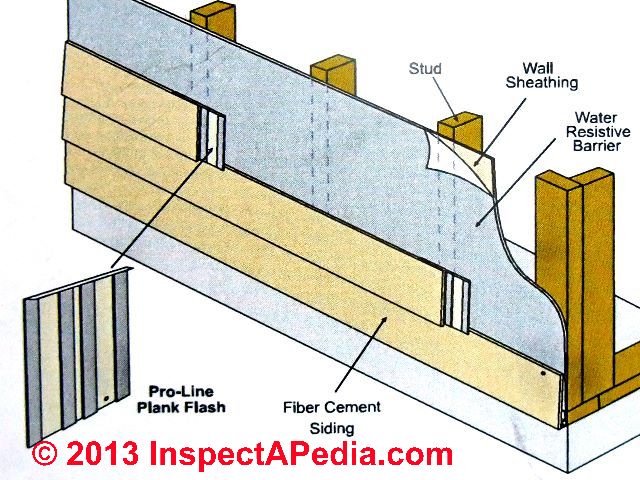

Even if the roof has been properly flashed against the sidewall this one hasn t water can still run down the side of the house and behind the siding causing rot. First step flashing must be installed before the siding so that the siding can cover the top of the flashing. And when those corners start to decay they become. Bent into an l shape.

The solution to rotting sidewalls is a small piece of bent metal called a kickout flashing at roofing suppliers which simply directs all that water away from the wall. But unlike fiber cement siding wood is almost sure to rot. The step flashing should be visible below the siding because siding installers should leave a 75 to 1 5 inch gap between the siding and the roof below. The question is can those be removed and then flashing slid under the horizontal butt joints in the 4 8 panels.

This gap can get covered over if the home has been roofed over since the siding was installed thus building up the roof height. I wish i had an easy answer for you because what you are attempting creates a couple of problems. Galvanized sheet metal bent at a 90 degree angle i e. Step flashing is used to provide a water tight connection where roofing adjoins a vertical juncture.

This flashing is typically field fabricated from a sheet of 26 ga. In my opinion some sort of impervious membrane should be installed over the sheathing and behind the flashing both of which should be lapped by the siding and the flashing should have 2 4 inches exposed between the concrete and the siding.