How Is Sheet Metal Guage Defined

That way if we suggest something like switching from 14 to 16ga to tighten a bend radius or save.

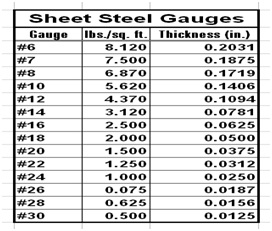

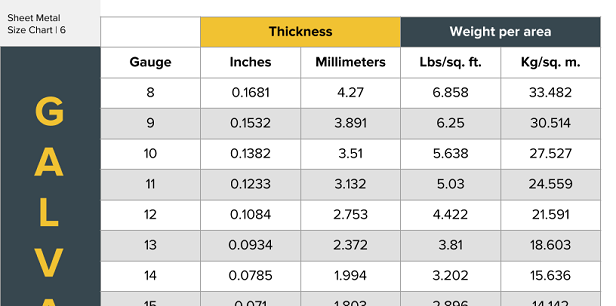

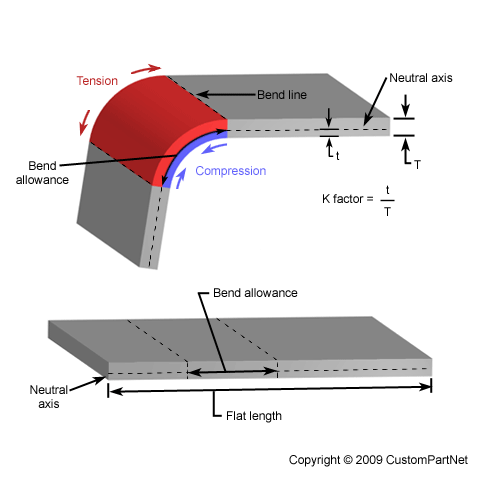

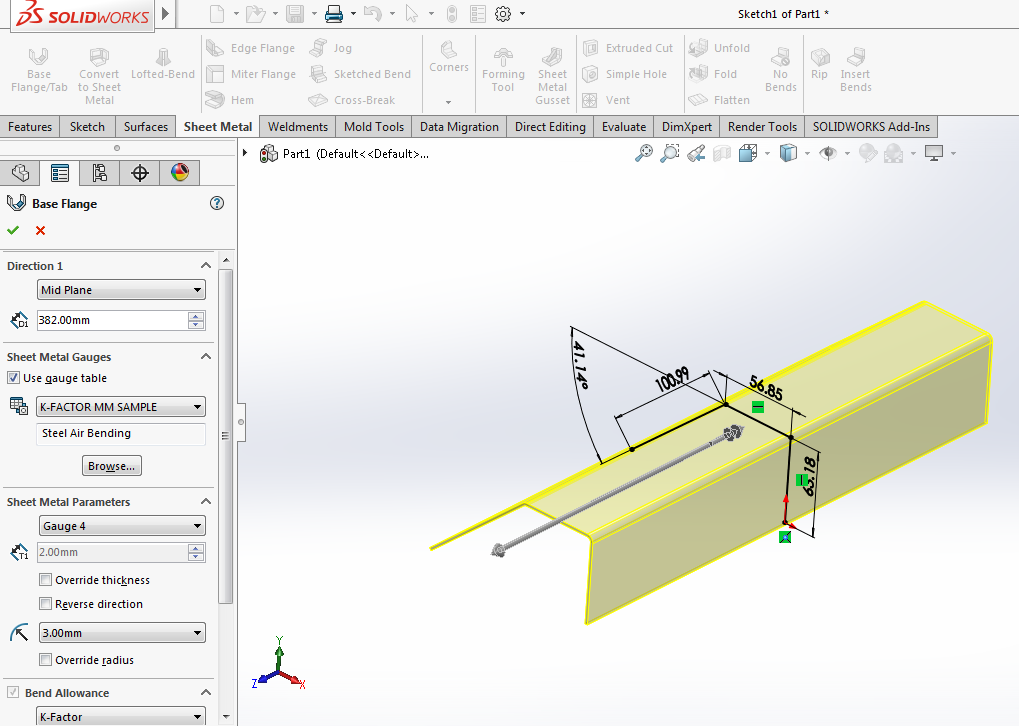

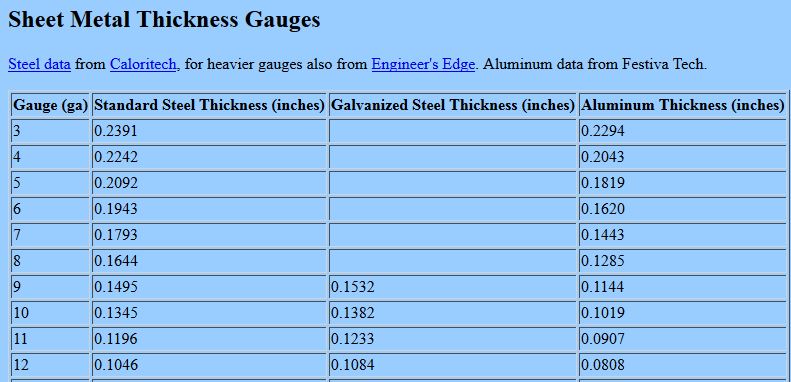

How is sheet metal guage defined. To help this blog will explain the gauge system and features a sheet metal gauge chart. The equivalent thicknesses differ for each gauge size standard which were developed based on the weight of the sheet for a given material. These choices will be defined in our sheet metal gauge table based on available tooling and material wall thickness. When working with sheet metal the term gauge is often used.

Gague are used to specify the thickness of a metal sheet. Originally used in the fields of medicine and jewellery the larger the. This is a great time saver because it ensures that the solidworks designer will not inadvertently create a model with a bend radius that we cannot manufacture with available tooling. Gague ga is a length measurement unit for diameters originating in north america and belongs to the browne sharpe metering system.

You should also know about gauge when discussing sheet metal with your friendly indiana based metal fabricator. Sheet metal is metal formed by an industrial process into thin flat pieces. A sheet metal gauge sometimes spelled gage indicates the standard thickness of sheet metal for a specific material. As the gauge number increases the material thickness decreases.

24 gauge 20 gauge 18 gauge and 16 gauge. Extremely thin sheets are considered foil or leaf and pieces thicker than 6 mm 0 25 in are considered. Sheet metal is one of the fundamental forms used in metalworking and it can be cut and bent into a variety of shapes countless everyday objects are fabricated from sheet metal. Kynar galvalume steel for metal roofing and gutters.

Sheet metal thickness gauges for steel are based on a weight of 41 82 pounds per square foot per inch of thickness. Sheet metal gauge size chart gauge or gage sizes are numbers that indicate the thickness of a piece of sheet metal with a higher number referring to a thinner sheet. Sheet metal is specified in gauge so rather than design in fractions of an inch you should really be specifying ga on part prints. When working with sheet metal it is common for the term gauge to be used someone unfamiliar with the gauge system may not understand what is meant by 18 gauge steel for example.

26 gauge 24 gauge 20 gauge 18 gauge 16 gauge 14 gauge 1 8 and 1 4.