How Is Sheet Metal Gauge Defined

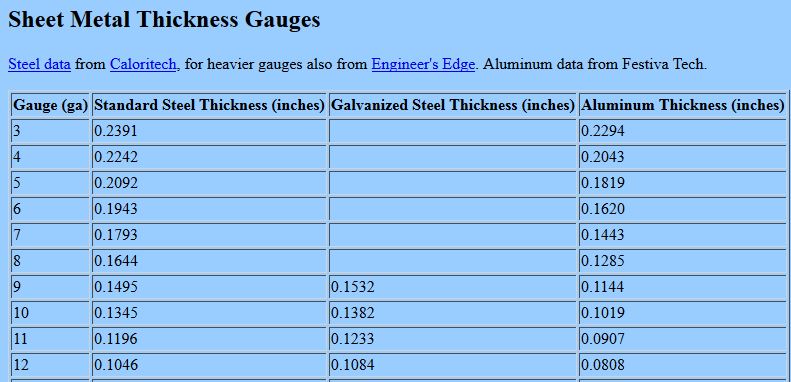

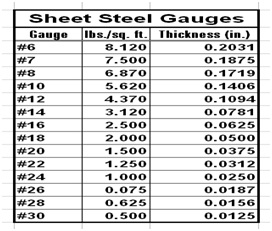

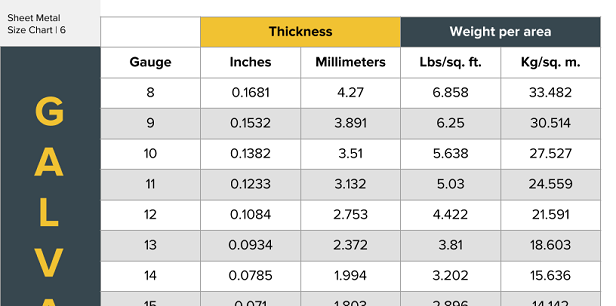

Sheet metal thickness gauges for steel are based on a weight of 41 82 pounds per square foot per inch of thickness.

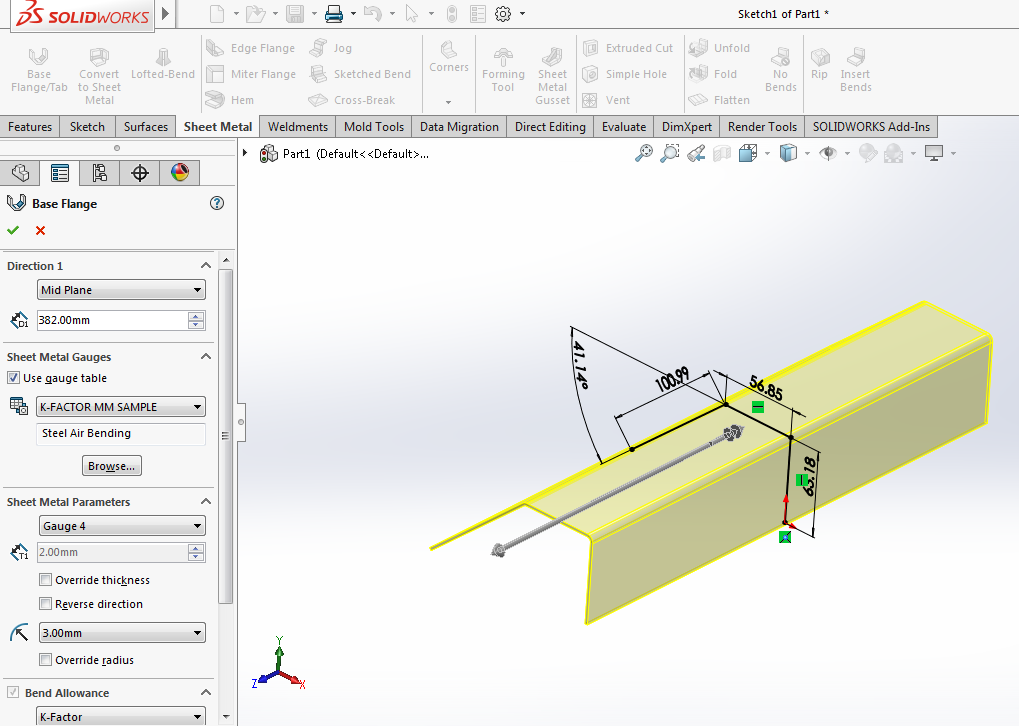

How is sheet metal gauge defined. To help this blog will explain the gauge system and features a sheet metal gauge chart. These choices will be defined in our sheet metal gauge table based on available tooling and material wall thickness. A measure of thickness for sheet metal. Gauge is a dimensionless number sometimes spelled gage and confusingly it works backwards.

Sheet metal is available in flat pieces or coiled strips. Gague are used to specify the thickness of a metal sheet. Then we use hands for horses and gauge written as ga for metal. Gague ga is a length measurement unit for diameters originating in north america and belongs to the browne sharpe metering system.

Usually a bigger number means there s more of something but 18 gauge steel is thinner than 16ga not thicker. Sheet metal gauge size chart gauge or gage sizes are numbers that indicate the thickness of a piece of sheet metal with a higher number referring to a thinner sheet. How gauge thickness works. So inversely the smaller the gauge number the thicker the metal.

As the gauge number increases the material thickness decreases. The coils are formed by running a continuous sheet of metal through a roll slitter. When working with sheet metal it is common for the term gauge to be used someone unfamiliar with the gauge system may not understand what is meant by 18 gauge steel for example. In most of the world sheet metal thickness is consistently specified in millimeters.

When working with sheet metal the term gauge is often used. Metal decking is most commonly 16 18 20 and 22 gauge in thickness. Why gauge thickness matters. Sheet metal is specified in gauge so rather than design.

A sheet metal gauge sometimes spelled gage indicates the standard thickness of sheet metal for a specific material. The larger the gauge number the thinner the metal.