Hot Rolled Sheet Metal Thickness Tolerance

An example of this can be found with hot rolled and cold rolled metal.

Hot rolled sheet metal thickness tolerance. The steel cools. However this cannot be said about cold rolled sheet and hot rolled sheet. Sheet metal gauge thickness chart 2019 10 24t01 36 33 00 00 when working with sheet metal the term gauge is often used. Conversion data chart standard gauges chart gauge tolerance chart useful data page.

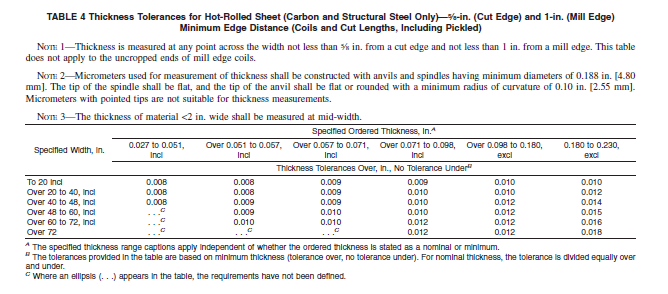

This keeps the market price of hot rolled steel lower. Hot rolled steel properties. The tolerances in the table and attachments reflect current manufacturing practices and commercial standards and are not representative of the manufacturer s standard gauge which has no inherent tolerances. Standard tolerances for cold rolled steel usually choosing material thickness is one of the first steps a designer takes when starting a project.

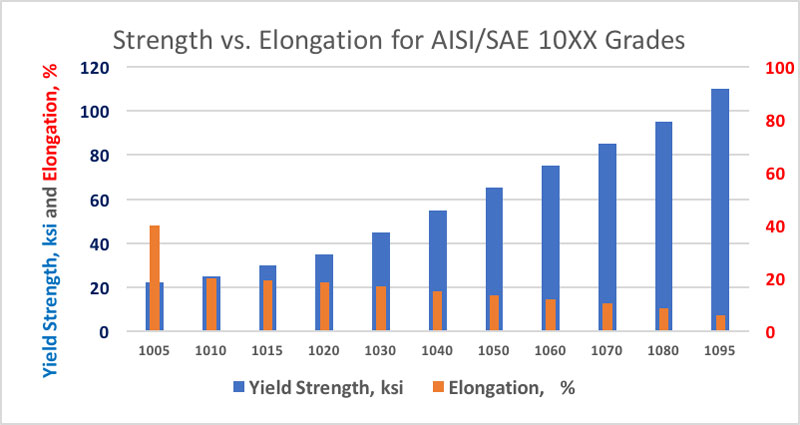

Some metal forming processes allow for more precision than others. As it is easy to form metal in high temperatures without any extra delays it is possible to produce it in larger quantities than cold rolled steel. Hot rolled mild steel seems to have a wider tolerance for amount of included carbon than does cold rolled steel and is therefore more difficult for a blacksmith to use. Sheet metal guage tolerances.

Any project where tolerances surface condition concentricity and straightness are the major factors. Dimensional tolerances are usually 2 to 5 of the overall dimension. Gague are used to specify the thickness of a metal sheet. With these two products the cold rolled product has low carbon content and it is typically annealed making it softer than hot rolled sheet.

Hot rolled steel starts as a large rectangular length of metal called a billet. We work with nominal thicknesses so it s important to know the thickness tolerance on the material you chose in order to know if the final product will be suitable for your application. Continuous rolling gives the desired final shape a metal sheet 3 mm and upwards or profile. During the rolling process the rollers bow slightly which results in the sheets being thinner on the edges.

The billet is first heated and then pre processed where it is.