History Of Sheet Metal Forming Process

The applied force stresses the metal beyond its yield strength causing the material to plastically deform but not to fail.

History of sheet metal forming process. Forming metal forming is the metalworking process of fashioning metal parts and objects through mechanical deformation. By doing so the sheet can be bent or stretched into a variety of complex shapes. Extremely thin sheets are considered foil or leaf and pieces thicker than 6 mm 0 25 in are considered. On the first day of our aluminium rolling technology course i run a session entitled machinery and process overview.

From these stresses the boundary conditions required to. While the term titanium sheet metal fabrication often conjures thoughts of modern industry and manufacturing the practice of sheet metal fabrication actually dates back to ancient egyptian jewelry. The workpiece is reshaped without adding or removing material and its mass remains unchanged. This is a commonly used manufacturing process that helps in manufacturing the parts for tons of known and unknown purposes.

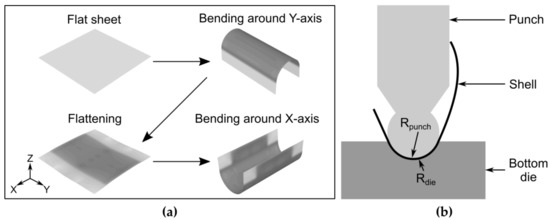

Forming operates on the materials science principle of plastic deformation where the physical shape of a material is permanently deformed. The method shown in fig. Sheet metal is formed cold. Curling is a forming process that involves de burring sheet metal to produce smooth edges.

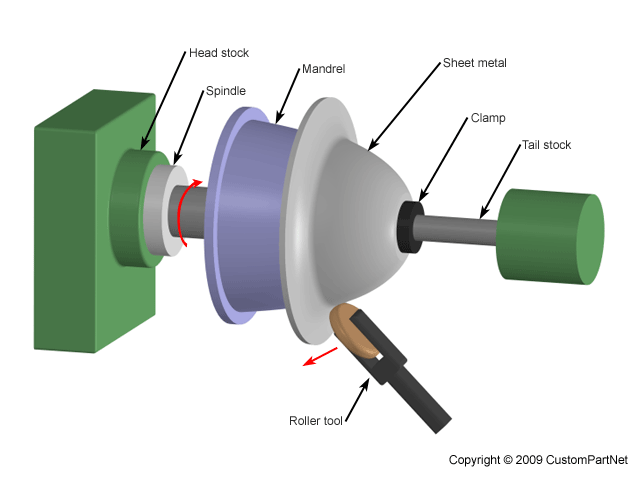

Classification of basic sheet forming processes bending deep drawing shearing. The die at the top is called a punch. Sheet metal forming involves forming and cutting operations performed on metal sheets strips and coils. From modern means to project completion to the tools of the trade here s our practically comprehensive timeline of the history of sheet metal fabrication.

For some set of process constraints a target part is optimally un formed to a flat blank. A brief history of metal rolling for sheet and plate products. People stop using primordial furnaces to pile alternated layers of iron and charcoal to liquefy steel. Part of this covers the history of metal rolling from the first known drawings of a mill to the state of the art rolling equipment available today.

Companies typically perform bending on sheet metal using either a brake press or similar machine press. Another common sheet metal forming process is bending. Through a combination of naturally found metals and prehistoric techniques gold and silver workers were able to craft a form of fabrication that served as the foundation of techniques used today. The sheet metal is placed over a die block at which point a punch presses down.

Sheet metal forming processes. The surface area to volume ratio of the starting metal is relatively high. Sheet metal forming process is done on a press and the parts are formed in between two die. Sheet metal forming processes are those in which force is applied to a piece of sheet metal to modify its geometry rather than remove any material.

Sheet metal fabrication can be traced back to eygptian jewelry using natural metals and prehistoric techniques. Sheet metal is metal formed by an industrial process into thin flat pieces. Tools include punch die that are used to deform the sheets.