Henry Fibered Aluminum Roof Coating Dry Time

This coating is designed for use on the roofs of barns homes garages and mobile homes.

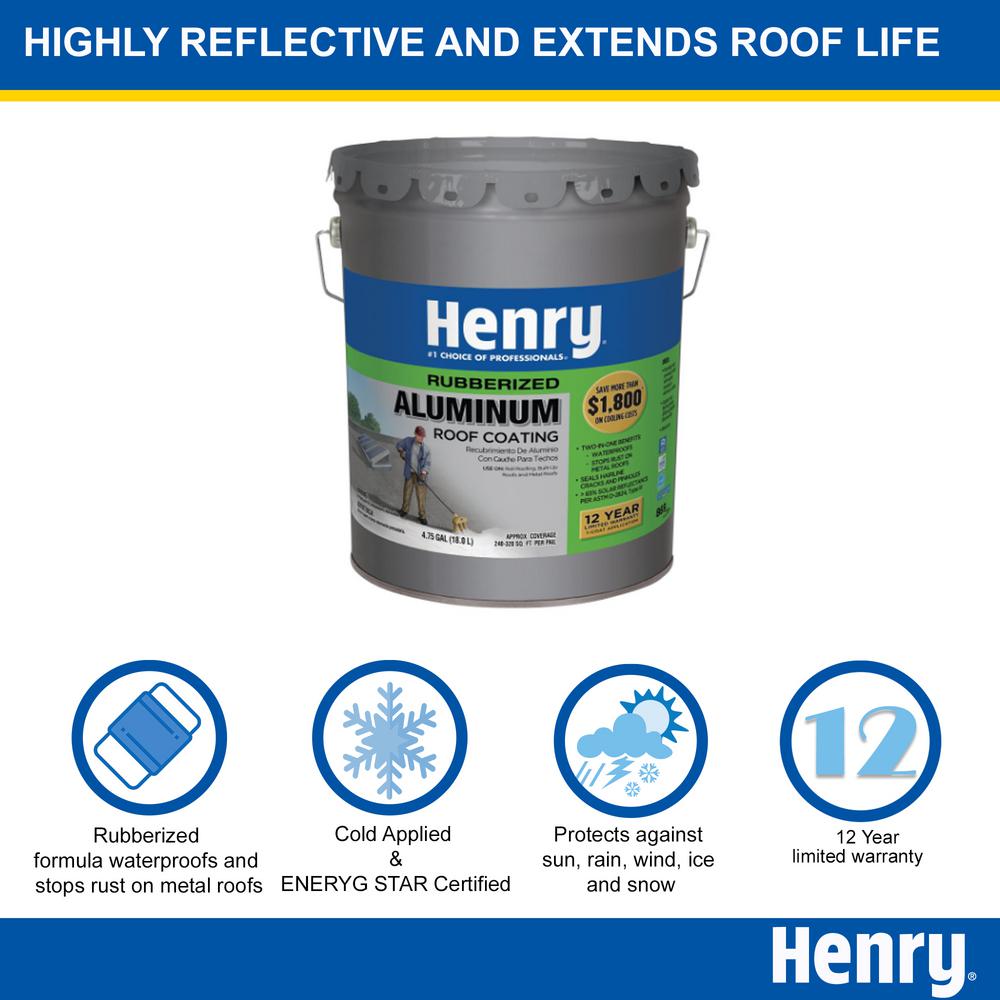

Henry fibered aluminum roof coating dry time. Roof repair and installation. With a henry cool roof coating a roof will reflect most of the sun s heat and uv rays help reduce energy bills extend roof service life and improve occupant comfort. Generally speaking roof coatings take 8 24 hours to thoroughly dry. Before coating the roof use a pressure washer or high pressure nozzle and water hose to wash the roof with a non filming detergent such as tsp or tsp substitute.

An emulsion coating will provide a firm base on which to apply the aluminum coating 5 to 10 days after the emulsion has cured. Henry 555 aluminum roof coating is an ultra premium fibered aluminum roof coating that forms a shiny tough reflective surface. Reflect up to 88 of the sun s heat and uv rays. 5 17 2017 henry 555 fibered aluminum roof coating application clean.

Henry 101 non fibered foundation coating. Fibered aluminum roof coatings provide the best coverage and dry fastest when outdoor temperatures are between 60 100 f 16 38 c with low humidity. 107 asphalt emulsion sealer and damp proofer. Henry cool roof products can.

203 roll roofing adhesive. This coating is designed for use on the roofs of barns homes garages and mobile homes. It can decrease heating and air conditioning costs and keeps the inside temperature of a building up to 20 f cooler in summer. Henry company 999 n.

800 el segundo ca 90245 tel. Henry 555 ultra grade fibered aluminum roof coating 5 gallon energy saver formula coating reduces interior temperatures by 20 degrees fahrenheit bright. Henry 555 fibered aluminum roof coating is an ultra premium fibered aluminum roof coating that forms a shiny tough reflective surface. Asphalt and damp proofing coatings.

The time span difference really depends on weather conditions. How long does it take a roof coating dry. Henry 104q quikdry asphalt spray primer. Repair fabrics and reinforcement products.

If an aluminum surface roof coating must be applied sooner to a new built up roof a water based emulsion coating should be used instead of a solvent based asphalt coating. Dew and high humidity will cause the coating to take longer to dry. Hot temperatures with dry weather will allow the coating to dry at a much faster rate. Subpar reflectivity composed of asphalt aluminum paste fillers hydrocarbon solvents and other chemicals aluminum coatings claim to lower roof temperatures and reflect ultraviolet rays.

X research source exposing the coating to excess moisture can result in a splotchy inconsistent finish. 201 fibered black roof coating.